compression test diesel vs regular|compression tester for diesel engine : factory This is the best option that I’ve found for a reasonably priced, high quality test gauge that reads up to 1,000 PSI (or 70 bar) which is what you’ll need for a diesel. Keep in mind that this is for the gauge only, you’ll also need to grab the correct adapter kit for your truck, if you keep scrolling I have the most popular adapters . See more Resultado da a partir de R$ 20,00. Ver Detalhes. O que é o Wind Banner da Atual Card? O Wind Banner é uma das principais ferramentas utilizadas em campanhas .

{plog:ftitle_list}

Formado em um conceito inovador o Grupo GFL é compost.

minimum compression for diesel engine

This is the best option that I’ve found for a reasonably priced, high quality test gauge that reads up to 1,000 PSI (or 70 bar) which is what you’ll need for a diesel. Keep in mind that this is for the gauge only, you’ll also need to grab the correct adapter kit for your truck, if you keep scrolling I have the most popular adapters . See moreIf you’re a professional mechanic or just someone that works on more than one type of truck, you’ll probably want to get a test kit that already . See moreDepending on which engine you have the test procedure will vary slightly in details, but the overall procedure is similar for most engines: 1. Disable fuel injection 2. Remove all glow plugs to reduce compression resistance 3. Use the correct adapter to thread . See more

I’ve put together the PSI ranges that you should be looking for when doing your compression test. Keep in mind that a lot of these are the specifications for these engines when new or . See more Regular compression testing is a crucial aspect of diesel engine maintenance that helps prevent catastrophic engine failures. By measuring the compression levels in each .

Evaporation Residue Testing chain store

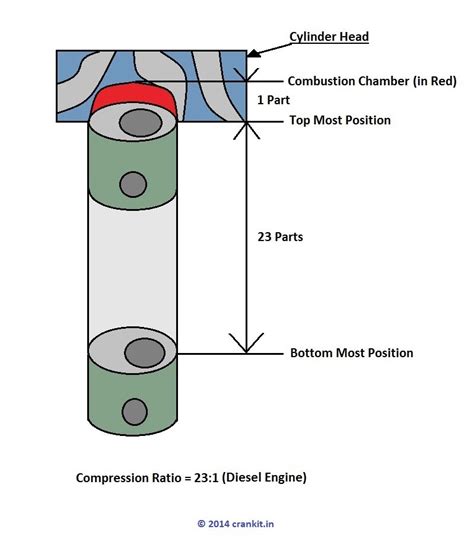

An engine compression test measures the compression level in each cylinder of an engine. It helps diagnose engine problems and determine if there is any. . Diesel Engines: Between 275-400 psi; Compression . When comparing gas and diesel engines, the combustion methods utilized play an essential role in determining their performance and efficiency.. Gasoline engines rely on spark ignition, while diesel engines use .

Compression test is more to test if there is a problem. If your compression is low, it could be a number of different issues. You can test the rings by adding oil to the cylinder and see if the compression is higher. Other than rings it can be difficult to determine the source of the issue. A leakdown test will tell you where the problem is.Diesel engines do not have spark plugs, but simply use extreme compression to generate the heat required for spontaneous ignition, also known as compression ignition. When this phenomenon occurs . The leak down test and compression test are both diagnostic tools used to assess the condition of an engine’s internal components. The leak down test measures the percentage of pressure loss in each cylinder, indicating potential leaks or worn piston rings, while the compression test measures the maximum pressure achieved during the compression .

Compare diesel vs gas in terms of engine performance, fuel efficiency, and cost. Determine the best type of truck for your needs with DPP! 888.99.DIESEL. . Regular maintenance for diesel trucks is typically more expensive than for gas-powered trucks, particularly because parts like turbochargers or fuel injectors can be costly to repair or . It is preferred for engines with a very low compression ratio. Using regular gasoline helps save money as it is cheaper. The rating number ranges between 85 and 87. Midgrade gasoline. . Step 3 – Test the cylinder. Dip your manometer gauge in each cylinder at a time. Have a partner ignite the vehicle and then turn it off. A stock 6.5l in our application will have a compression ratio of 21.5:1 - 22.5:1. If you do the math, this means that in a perfect world, each cylinder will read between 301 and 315 PSI on the compression stroke. To do a compression test, you'll need first need a diesel application compression testing gauge.Compression Testing vs. Leak Down Testing. There has been great confusion encountered regarding compression tests and leak down tests. A compression test is typically done prior to a leak down test and is an easy way to determine the internal health of your engine. You can have a qualified mechanic do this or you can do it yourself with the .

If you're looking for a universal diesel compression tester that's suitable for various applications, the DAYUAN Diesel Engine Compression Tester Kit is an excellent choice, offering a range of 0-70 Bar/0-1000 Psi and coming with 9 different glow plugs and 4 injector adaptors.. This kit is designed to provide you with flexibility and versatility, making it an ideal .

In a compression test, the modulus of elasticity can be calculated from the initial, linear portion of the stress-strain curve where the material behaves elastically. . This data is typically recorded at regular intervals throughout the test. In many modern testing machines, the data acquisition is automated, and the machine directly records . Doing a compression test, is a good way to measure the condition of, the rings, cylinders, and valves. So, if your engine is running rough or is lacking power, consider doing a compression test. Also, it is important to perform a compression test every time a tune-up is done, as part of preventative maintenance. The regular engine compression test uses a single gauge and measures the maximum instantaneous compression built by that cylinder. A compression test uses the engine turning to generate the compression in the cylinder for the compression stroke, in which both intake and exhaust valves are closed. A leak down test uses a set of gauges and . Premium vs. Regular Gas Using premium gas (when the manufacturer recommends) maintains performance and fuel economy. It also reduces the chance of engine “knocking.”

The Origin of Distillate Fuel Oil or Diesel. This fuel variant is a byproduct of the fractional distillation of kerosene but a less volatile type, which works perfectly with the compression-ignition power mill or diesel engine .A compression tester is a quick and easy way to show if a catastrophic problem exists, and on which cylinder(s). If your engine drops a cylinder or two, a quick compression test will determine if something is physically wrong inside the .An octane rating, or octane number, is a standard measure of a fuel's ability to withstand compression in an internal combustion engine without causing engine knocking.The higher the octane number, the more compression the fuel can .

This video shows you how to test the cylinder compression pressure test in common rail diesel engines Put the compression test adapter into the engine's first cylinder. Look down on the engine to figure out which cylinder is closest to the front of the engine. Note the circular cylinders and the timing belt on the engine’s front. . For diesel engines, the optimal PSI is between 275 and 400. Low individual readings indicate cylinder-specific .

diesel engine compression chart

diesel compression test through injector

A compression test measures the dynamic pumping pressure of the cyclinder when the crankshaft is rotated. A compression test is an extremely important engine diagnostic procedure. It should be done on any diesel you are planning to purchase. More than any other test, it can tell you if you are purchasing a healthy engine.

The relative compression test is a simple, easy test that can save you, your techs, and your customers hours of frustration and headache. It just requires a .1952 Shell Oil film showing the development of the diesel engine from 1877. The diesel engine, named after the German engineer Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is called a compression-ignition engine . This tutorial will teach you everything you need to know to do a compression test on any engine. I cover the process from start to finish including what comp. Worn valves, valve seats and valve train normally cause uneven compression. If only one cylinder has low compression, a burned exhaust valve, broken valve spring or broken piston rings are indicated. Dry/Wet Compression Testing – The classic wet/dry compression test is intended to detect worn piston rings by comparing cranking compression .

If you're a car owner, you know the importance of keeping your vehicle in good condition. Regular maintenance checks are key to ensuring your car runs. . The compression tester will typically connect to the spark plug hole or the diesel injector port. . It is recommended to perform a compression test every 30,000 miles or during a tune-up. Generally, each cylinder should have 300 to 500 PSI, and all cylinders in a single engine should measure within 10 percent of each other. If the compression in the engine is too low, too high or .

Of the diesel trucks we've tested on our 75-mph real-world route, only two returned 20 mpg—a 2018 Ram 2500 with the S/O Cummins diesel and a 2023 Ford F-250 Super Duty fitted with a High-Output .

Evaporation Residue Testing convenience store

Mega Eletrônicos - Compras no Paraguai - Loja de Eletrônicos

compression test diesel vs regular|compression tester for diesel engine